Guaranteeing food supplies is a growing issue. With a growing global population, climate change and ocean acidification disrupting crops and fish stocks, many countries face serious challenges in ensuring food security.1 As well as issues affecting food production worldwide. Another important aspect for food security is food storage and preservation. Food sensor technology plays a key part in quality crop storage to prevent food insecurity.

Improving Shelf Life with Food Sensor Technology

Cereals are one of the key sources of calories for the world’s nutritional needs. Maize, in combination with rice and wheat, provides at least 30 % of calories for more than 4.5 billion people, with developing countries most heavily dependent on these types of crop.2 However, when crops such as maize are stored, there are numerous ways that the crop can deteriorate and become wasted, including damage from humidity, insects, and microorganisms.3 It is estimated that $500 million to $1 billion of maize is lost in the developing world each year from these last two factors alone.4

This means there is a strong impetus both economically and for human health to improve cereal storage methods, reducing losses. Historically, it was common to use fumigants, gaseous pesticides, in barns to kill invasive insects and microorganisms but now, it has become more common to use types of food sensor technology, such as, modified atmospheric conditions to achieve the same goals with fewer concerns about health and safety.5

Modified Atmospheric Conditions

A modified atmosphere, or controlled atmosphere, is one in which the normal ratio of gases in the air is replaced with a specific combination of gases, often for the purposes of food preservation.6 Modified atmospheres are commonplace now in food packaging and transport, where they can be used to extend the lifetime and quality of produce such as meat and fruit, reducing the need for preservatives.

Storage of grains is typically done in environments composed partly of carbon dioxide, nitrogen, and oxygen. Increased carbon dioxide concentrations and lowered oxygen concentrations can have a lethal effect on insects and increasing nitrogen and oxygen can be used to control the relative humidity of the environment, reducing deterioration of crops and the risk of spoilage.7

However, the chemical composition of the atmosphere in a grain bin is not a static one. Respiration of moulds and insects can lead to elevated carbon dioxide levels8 and stored seeds and cereals produce small amounts of not just carbon dioxide but also highly toxic carbon monoxide gas.9 Carbon dioxide rates of production may also be a better and more effective way of the early detection of spoilage than monitoring other conditions in the storage area such as temperature.10

Food Spoilage Sensors and Gas Monitoring

To ensure that any unnecessary wastage is avoided by ensuring that modified atmospheric conditions are kept at their optimum ranges by food sensor technology, and that any increase in carbon dioxide production indicating spoilage can be detected, rapid-response, online sensors with good sensitivity are needed.

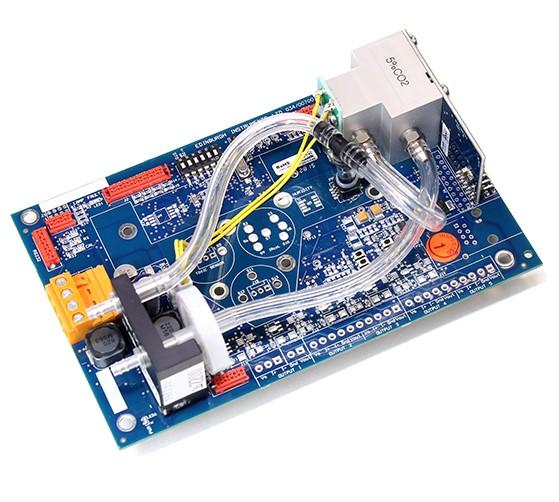

Edinburgh Sensors offer a diverse range of infra-red based sensors and monitors suitable for operation in the typical conditions found in grain silos or barges. These include the Gascard11, the Guardian NG12 and the GasCheck13 with many of these detectors being both suitable for carbon dioxide detection, carbon monoxide, and other hydrocarbon gases. Drawing on their 40 years of experience in the design and manufacture of such gas monitors, Edinburgh Sensors offers technical support and advice with every purchase as well as the possibility of custom solutions where required.

Food Sensor Technologies: Gascard NG – Co2 Gas Sensor

Given the challenges posed by the potential humidity levels in the cereal storage environment and the need to ensure accuracy of a range of different carbon dioxide concentrations, for example, if high carbon dioxide levels are being used to suppress insect life, the Gascard NG11 offers the perfect solution for possible gas monitoring needs. Measurements are unaffected by humidity (in conditions between 0 – 95 %) relative humidity and, to ensure carbon dioxide concentrations are measured accurately irrespective of fluctuations in the local environment, the onboard pressure and temperature sensors are capable of compensating for any fluctuations.

The Gascard NG can measure CO2 concentrations in the range of 0 – 5000 ppm and is also available in the form of the Boxed Gascard13, which has a convenient external housing for immediate installation and connected by USB for continual data logging and monitoring. The response time is less than 10 seconds, making it a fast and reliable way to immediately start obtaining data on storage conditions.

With a similar, easy-to-install format, the Guardian NG also offers excellent, environment compensated, carbon dioxide detection accuracy, with ±2% accuracy over the entire detection range of the instrument (0-3000 ppm). The on-device screen and set-up menus make it easy to install and there is also an onboard alarm where the gas monitor can act as part of an early warning system to minimize any potential losses of product.

All of Edinburgh Sensors cutting-edge infra-red detectors are suitable for use in government, trader or farm cereal storage locations as the sensors are capable of handling a wide type of environmental conditions, whether for short or long term storage.

Keep Up To Date

If you would like to know more about the interesting food sensor technology work done at Edinburgh Sensors you can easily follow us on our social media platforms using the links below, or sign up today for our infrequent newsletters.

References

- Global Food Security Index 2018: Building Resilience, (2018)

- Shiferaw, B. et al. (2019). Crops that feed the world 10. Past successes and future challenges to the role played by wheat in global food security. Food Secur., 2013, 5, 291–317.

- Suleiman, R. et al. (2013). Effects of Deterioration Parameters on Storage of Maize, Nat. Sci. Res., 3, 147–165.

- Tuite, J., and Foster, G. H. (1979). Control of storage diseases of grain. Annual Review of Phytopathology, 17(1), 343-366.

- Navarro, S., and Navarro, H. (2016). Emerging Global Technological Challenges in the Reduction of Postharvest Grain Losses. Proceedings of the 15th International Cereal and Bread Congress, 39.

- Correct Gas Concentrations for Atmospheric Packaging, (2018)

- Jayas, D. S. and Jeyamkondan S. (2002). Modified atmosphere storage of grains meats fruits and vegetables, Eng., 82, 235–251.

- Pekmez, H. (2017). Cereal Storage Techniques: A Review, Agric. Sci. Technol. B, 6, 1–6.

- Reuss, R. and Pratt, S., (2001). Accumulation of carbon monoxide and carbon dioxide in stored canola, Stored Prod. Res., 37, 23–34.

- Maier, D. E. et al. (2006). Monitoring carbon dioxide levels for early detection of spoilage and pests in stored grain. Proceedings of the 9th International Working Conference on Stored Product Protection PS10-6160.

- Gascard NG, (2019)

- Guardian NG (2019)

- Gascheck (2019)

- Boxed GasCard (2019)