For iron and steel, one of the most common approaches for hardening these relatively soft materials is to perform heat treatment under endothermic atmospheres. There are many methods for heat-treating metal alloys, some of which include case-hardening or surface hardening and annealing, but the general purpose of the treatment is to help improve the durability or hardness of the material.1

To achieve these improvements in the hardness properties for alloys, heat treatment involves several stages. These are generally divided into annealing, quenching, and tempering. Annealing involves first heating the metal to a given temperature for a certain length of time and then using a controlled rate of cooling. Quenching involves rapid temperature reduction of the material to make the alloy very hard. Often such hardness can lead to brittle materials, so tempering can be used to restore some of the elasticity.2

Environmental Factors

Careful control of conditions throughout all of the stages of heat treatment is required for maximum control of the final material properties, including that of the surrounding environment. Using endothermic gases, such as CO, H2, and N2, is part of maintaining fine control of the heat treatment processes.3

The purpose of the endothermic environment is to ensure the right environmental conditions for the hardening process. This helps ensure that the correct chemical reactions occur to preserve the desired physical properties of the metal. Such atmospheres can also be used as carrier gases for other species in processes such as carburizing or carbonitriding. Part of the hardening process involves the decomposition of the carbon-rich gases causes migration onto the surface layers of the metal.4

As well as ensuring the correct concentrations of endothermic gases in heat treatment for their thermal properties, CO2 concentrations need to be controlled as excess CO2 levels can lead to unwanted oxidation reactions. O2 can also have similar effects on metals such as iron. It can also be advantageous to control excess CO levels, as it is often produced from side reactions between oxygen and hydrocarbon gases but can be involved in ‘carbon reversal’ processes that lead to the production of soot.5

Process Control

For heat treatment in endothermic conditions, it is therefore imperative to have highly controlled and monitored gas concentrations, as well as a way of monitoring potential fluctuations in the concentrations that are reliable over a large temperature range.

Non-dispersive infrared (NDIR) gas sensors are ideal for detection of a range of hydrocarbon gases and well suited for detection of many of the species involved in endothermic protection as they absorb IR light very strongly, making it a highly sensitive detection technique.

Furnace Sensors and Feedback

Edinburgh sensors have been world leaders in the design and manufacture of NDIR sensors since opening in 1980.6 They offer a range of gas monitors that are suitable for detecting one gas type at a time with built-in microcontroller processing to allow onboard corrections for changes in pressure and temperature conditions.

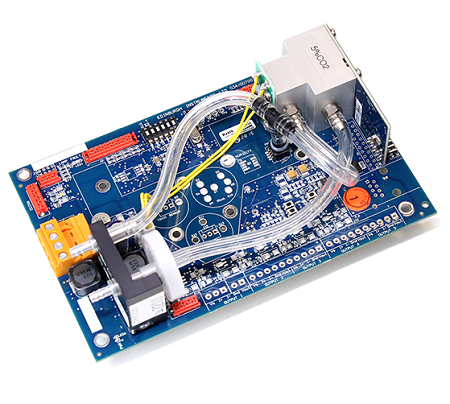

Suitable for detection of CH4, CO2, and CO, Edinburgh Sensors offers the GasCard NG7 and Guardian NG NDIR-based gas monitors.8 Both are highly sensitive monitors, capable of detecting CO2 concentrations between 0 – 5000 ppm and CH4 and CO levels between 0 – 100 %.

The Guardian NG8 offers an accuracy of ± 2 % across the full detection range and temperature compensation between 0 – 40 °C, while measurements are unaffected by humidity conditions in the 0 – 95 % relative humidity. The sensor is housed in an IP54 compliant casing which in addition comes with a convenient monitor for showing current and historical gas concentrations and built-in alarms that can be programmed directly on the device. The low response time (T90 < 30 s from sample inlet) means that the Guardian NG is ideal for providing continual monitoring and live feedback on even the smallest changes in conditions in the heat treatment chambers.

Gascard NG

There are two variants of the GasCard NG7, one of which comes with external housing for easy mounting and installation.9 The GasCard series comes with field-replaceable IR sources for easy maintenance that does not require site visits and offers similarly impressive accuracy over the full range (± 2 %) as the Guardian NG. The GasCard is a highly adaptable system, that can come with a variety of connection types, including R323 and USB, which means that the sensor can be integrated into detection and control systems for environmental systems. This means that, despite what gases are produced as part of the heat treatment process, feedback from the GasCard can be used to keep environmental conditions constant and ensure the finest of process control for optimum results.

For process design and integration into existing feedback systems, Edinburgh Sensors also offers pre- and post-sales support and can help design custom solutions for any specific gas sensing requirements if necessary.

References and Further Reading

- Oberg, E. (Ed.). (1920). “Heat-treatment of steel: a comprehensive treatise on the hardening, tempering, annealing and casehardening of various kinds of steel, including high-speed, high-carbon, alloy and low-carbon steels, together with chapters on heat-treating furnaces and on hardness testing. The Industrial Press.

- Gopalan, R., & Narayan, P. (2011). Review of thermo-physical properties, wetting and heat transfer characteristics of nanofluids and their applicability in industrial quench heat treatment. Nanoscale Research Letters, 6(1), 334.

- Dawes, C., Tranter, D. F., & Smith, C. G. (1980). Reappraisal of Nitrocarburizing and Nitriding When Applied To Design and Manufacture of Non-Alloy Steel Automobile Components. Studies in Surface Science and Catalysis, 1693(April), 60–68. https://doi.org/10.1179/030716979803276390

- Christiansen, T. L., & Somers, M. A. J. (2009). Low-temperature gaseous surface hardening of stainless steel: The current status. Zeitschrift Fuer Metallkunde/Materials Research and Advanced Techniques, 100(10), 1361–1377. https://doi.org/10.3139/146.110202

- Edenhofer, B., Gräfen, W., & Müller-Ziller, J. (2001). Plasma-carburising – A surface heat treatment process for the new century. Surface and Coatings Technology, 142–144, 225–234. https://doi.org/10.1016/S0257-8972(01)01136-7

- Edinburgh Sensors (2019) https://edinburghsensors.com/about/about-us/

- Gascard NG, (2019), https://edinburghsensors.com/products/oem/gascard-ng/

- Guardian NG (2019) https://edinburghsensors.com/products/gas-monitors/guardian-ng/

- Boxed GasCard (2019) https://edinburghsensors.com/products/oem/boxed-gascard/