Nothing says summer like biting into a juicy, perfectly ripe strawberry. A bright red package, with a soft, sweet aroma and a firm texture are all the signatures that the fruit is ripe and ready to be eaten. However, with just a day or two more, a fruit that may have been a delightful treat can become a mushy, flavourless mess and home to mould. Fruit ripening gas can play a big part in ensuring your fruit stays fresher for longer.

The difference in experiencing eating well-ripened fruits or under/over-ripe specimens is so dramatic that perceived ripeness has a strong influence on consumer purchasing behaviour and the probability of them purchasing a fruit.1 As there may be a significant time period between fruit picking and its arrival on the supermarket shelf, it is important to control the ripening process for fruits so they can be sold in their prime.2

Mechanisms of Fruit Ripening

The fruit ripening process is a natural part of the maturation of fruits to obtain their optimal flavour, quality, and textural properties. This process involves a series of changes in the composition of the fruit, including the conversion of starch to sugar, that are triggered by a cascade of chemical and biochemical reactions in the fruit.3

The involvement and producing of chemicals during ripening means that the process can be controlled by changing the atmospheric composition surrounding the fruit. One of the most widely used chemicals for speeding up the ripening process is ethylene, so much so that it is known as ‘the ripening hormone’.4 Ethylene is naturally produced by ripening fruits where it can trigger biochemical cascades and physiological responses such as the aging and shedding of petals or additional growth in some cells. Some fruits, such as bananas, produce large amounts of ethylene which can have detrimental effects on the lifetimes of fruit stored alongside them.

Carbon Dioxide and Fruit Ripening Gas

Ethylene though is not the only chemical species that drives the lifecycles of fruit. Carbon dioxide (CO2) is another by-product of the ripening process and controlling CO2 concentrations can be used not to adjust the rate of the ripening process and help tune some of the properties and characteristics of the final fruit.5

For example, with kaki fruit, under-ripened fruit can taste very astringent and unpleasant but their firmer texture is better suited to transportation and risks less damage to the flesh of the fruit. By ripening the kaki with a carbon dioxide atmosphere, the improved flavour of the ripe fruit can be achieved while maintaining the solidity of the unripened fruit. Controlling the CO2 atmospheric concentrations is also used for many oranges and citrus fruits where it can help change the colour of the fruit from an unappetising green to orange without impacting the flavour.

As well as ripening, careful control of CO2 and oxygen (O2) levels can help with preservation and freshness. As fruits continue to ‘breathe’ and produce various gases, the atmospheric concentrations can change with time. For apples, use of controlled CO2/O2 atmospheres can mean the fruit flavour and quality remains nearly unchanged for as long as nine months after harvesting.6

Fruit Ripening Gas Sensing Solutions

Maintaining optimal CO2 concentrations is a complex task that requires highly sensitive online monitoring with feedback loops for optimisation. For this, Edinburgh Sensors are the market leaders with over forty years of experience developing highly sensitive, rapid response near-infrared sensors for detection of hydrocarbon gases and CO2.

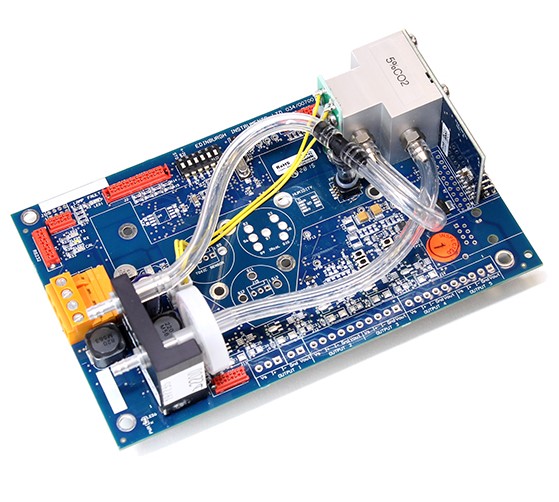

Depending on the exact needs, Edinburgh Sensors offers a range of CO2 sensors including the Gascard NG7, Guardian NG8, the IRgaskiT9, and the Gascheck.10 Of these, the Gascard NG offers a huge amount of flexibility in its set-up, monitoring options and integration into connected systems.

There are two versions of the Gascard NG available. It can be purchased either as the stand-alone card or as the Boxed Gascard11, that contains the Gascard NG card inside but in a pre-built housing to minimise installation and set-up time. Given the low concentrations of CO2 and O2 that are often optimal for controlled atmospheric preservation of fruits (for apples, between 2 – 6 % of CO2 and 2 – 3 % of O2) then the high sensitivity and accuracy of these sensors are essential for this application.

For example, The Gascard can detect CO2 concentrations in the range of 0 – 5000 ppm. It is also able to work under realistic temperature and humidity conditions and is capable of providing accurate readings over humidity conditions spanning 0 – 95 %. Another powerful feature of the Gascard NG is that, by using RS232 communications, the Gascard can be integrated with other control or data logging devices easily and there is also with the option for onboard LAN support where required. This means it is relatively straightforward to set up feedback systems to constantly monitor, log and adjust the atmosphere around the fruit, ensuring the produce is always at its best.

With the ability to reduce waste – ripening fruit may overripen other nearby fruit – optimise ripening at the time of sale and improve product quality, Edinburgh Sensors instruments offer cost-efficient and high-quality devices for online monitoring of CO2 levels.

References

- Bruhn, C. et al. (1991) “Consumer Perception of Quality.” Journal of Food Quality, 14: 184–95

- How old are the ‘fresh’ fruit and vegetables we eat, https://www.theguardian.com/lifeandstyle/2003/jul/13/foodanddrink.features18, (accessed May 2019)

- Giovannoni, J J,. (2001) Molecular Biology of Fruit Maturation and Ripening. Rev. Plant Mol. Biol. 52: 725–749.

- Barry, C.S. et al.. (2007) Ethylene and Fruit Ripening Journal of Plant Growth Regulation 26: 143–59. https://doi.org/10.1002/9781118223086.ch11.

- Burg, Stanley P., et al.. (1969) Interaction of Ethylene, Oxygen and Carbon Dioxide in the Control of Fruit Ripening. Qualitas Plantarum et Materiae Vegetabiles 19 1–3: 185–200. https://doi.org/10.1007/BF01101152.

- Streif, J. et al. (2016). Production of Volatile Aroma Substances by ‘Golden Delicious’ Apple Fruits after Storage for Various Times in Different CO 2 and O 2 Concentrations Journal of Horticultural Science 63 (2): 193–99. https://doi.org/10.1080/14620316.1988.11515847.

- Gascard NG, https://edinburghsensors.com/products/oem/gascard-ng/, (accessed May 2019)

- Guardian NG, https://edinburghsensors.com/products/gas-monitors/guardian-ng/, (accessed May 2019)

- IRgaskiT, https://edinburghsensors.com/products/oem/irgaskit/, (accessed May 2019)

- Gascheck, https://edinburghsensors.com/products/oem/gascheck/, (accessed May 2019)

- Boxed Gascard, https://edinburghsensors.com/products/oem/boxed-gascard/, (accessed February 2019)

Stay in Touch

We hope you have enjoyed learning more about how our range of products can help in the process of fruit ripening. If you want to hear more about our fruit ripening gas solutions, or anything else, please keep up to date with us on our social media platforms. Or, read all the latest news and applications from Edinburgh Sensors by signing up to our monthly newsletter.