NDIR Sensor for Non-Dispersive Infrared Detection

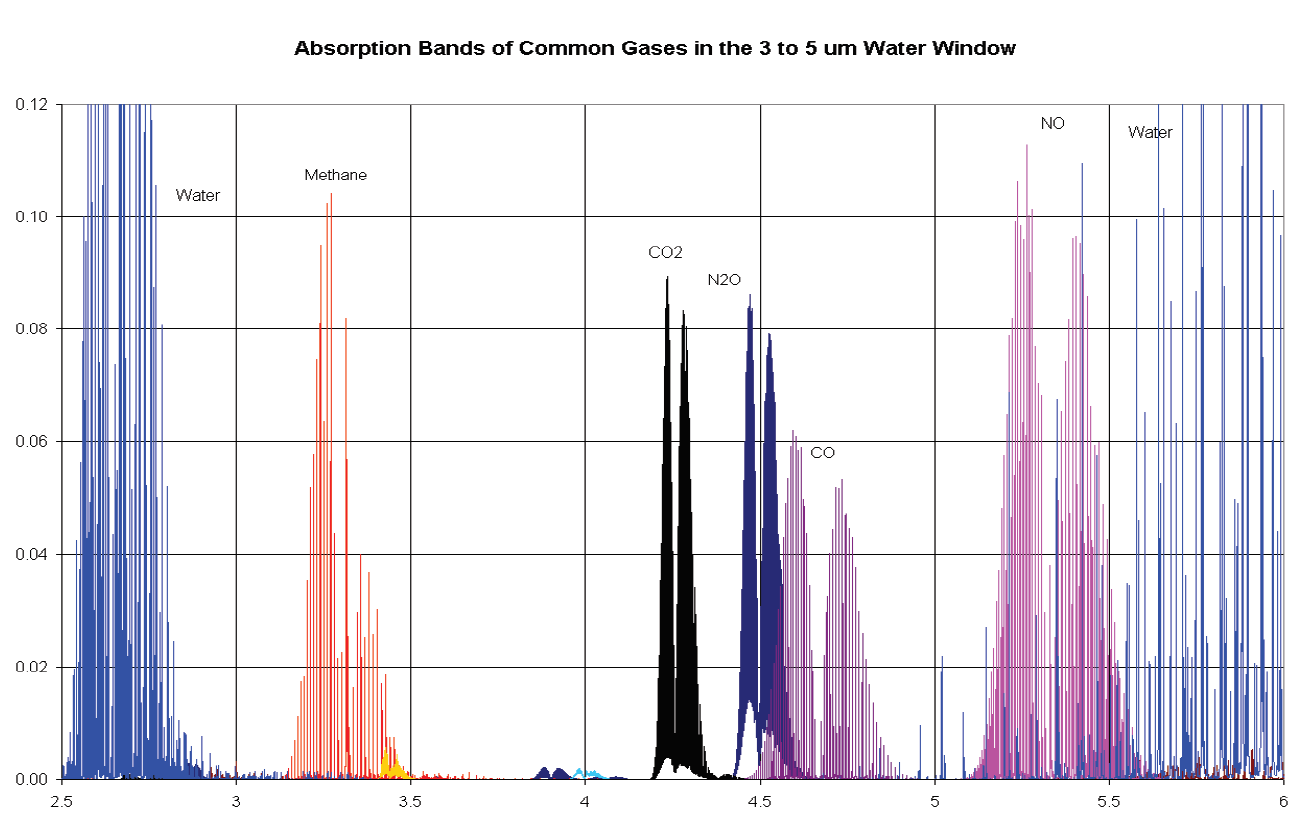

Infrared (IR) techniques are very popular in gas detection technology since many gases have characteristic vibration/rotation absorption spectra with narrow, non-overlapping bands in the infrared spectrum between 2 μm and 20 μm.

Since it is often possible to identify and detect individual absorption bands which are virtually unique to a gas or group of gases, IR gas sensors can be selectively sensitive to a specific gas or group of gases.

Most infrared sensors measure absorption by the gas and therefore have signals present at all gas concentrations. As a result, it is easy to detect a fault in the system so that infrared gas sensors are generally regarded as ‘fail safe’.

IR Gas Sensors

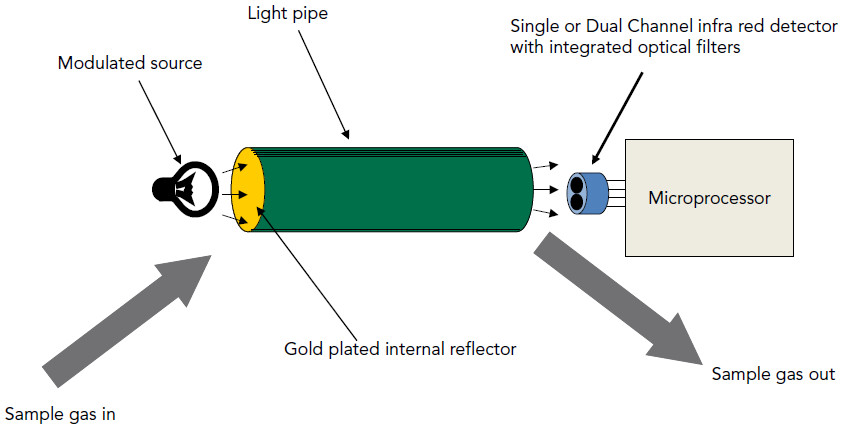

Commercial IR gas sensors generally consist of an infrared source, a detector, a gas cell/path, a wavelength selection device and some optical components (lenses or more usually mirrors) to couple the radiation from the source through the gas cell to the detector.

The sample gas passes through the gas cell and the detector measures the radiation at the absorption band wavelength of the target gas. When no target gas is present there is no absorbance so the signal reaching the detector is at a maximum. When the target gas is present in the path, the detected signal reduces as the target gas concentration increases.

Non-dispersive infrared (NDIR) sensors

Key to this process is the selection of the correct absorption wavelength for measurement. The wavelengths from the optical source can be separated spatially using prisms or diffraction gratings. This is known as dispersive separation. Alternatively, an optical filter can be used which allows only transmission of the required wavelength. This is a non-dispersive infrared (NDIR) approach. It has been shown (Jacquinot P. 1954 J. Opt. Soc. Amer. 44, 761-765) that optical filters are typically 1000 times more efficient than gratings and up to 100,000 times more efficient than prisms at separating IR wavelengths, so NDIR gas sensors offer real performance advantages over dispersive systems and are the systems of choice.

Eliminating Errors

Unfortunately, many factors other than the presence of the target gas can affect the detected signal. These include changes in the source output, the filter transmission and detector response with both time and temperature, as well as errors caused by the electronics and dirt on the optical components. These errors can be overcome through the use of a second, reference channel, operating at a wavelength close to the measurement wavelength. All these factors will equally affect the reference channel, so by taking a ratio of the two channels, they can be eliminated, giving a stable, reliable measurement. Sensor designs ensure that the reference beam follows essentially the same path through the optical components as the measurement beam to eliminate any variations due to non-uniform contamination of the optics with the addition of an electronically modulated source and digital signal processing a reliable, long-term stable gas detection system is created. Edinburgh Sensors Ltd established the basic design of this type of NDIR Sensor 4 years ago and we have been perfecting it ever since.

Are you looking for an NDIR sensor?

For further information on our range of NDIR sensor technologies, including price, please do not hesitate to get in touch.