Comfortable working conditions are so important for workers that minimum working temperatures are enshrined in UK law.1 As well as having an impact on overall productivity and health issues such as eyestrain2, ensuring good indoor environments can also be used to impact positively the energy efficiency of a building.3

For most indoor areas, it is heating, ventilation and air conditioning (HVAC) systems that are at the heart on controlling environmental conditions, such as temperature and air quality. For many buildings having a centralised HVAC system is a popular choice as it means all the necessary infrastructure can be housed in one section of the building or externally and centralised systems typically simplify maintenance needs as there are fewer compressor units distributed throughout the building.4

A centralised HVAC system means that all of the key equipment for heating and ventilation is in the same area and networks of ducting are used to transport any hot (or cooled) air around the building. As this part acts as a central hub for the entire building, any issues at the HVAC source can quickly spread into building-wide problems. For health concerns such as Sick Building Syndrome, the Health and Safety Executive advice identifies ventilation units as a potential cause and encourages their regular maintenance.5 This is because it is thought gas contamination in ventilation systems from species such as carbon dioxide and volatile organic compounds may be a contributing factor in Sick Building Syndrome.

Gas Monitoring for HVAC Systems

Centralised HVAC systems are commonplace in schools, banks, offices, and any large complexes. This helps reduce noise from the HVAC system being a problem for workers, as well as improving building aesthetics as the ducting for air transport can be very discrete. The compressor units are typically water-cooled and, for buildings where different sections have different HVAC requirements, valves can be installed to optimise conditions in these regions.

With the centralised infrastructure, installation of gas monitoring systems in the area is essential. Often, outdoor air is circulated to avoid the build-up of unwanted gases or particulates, but for buildings where this is not possible, air quality is controlled through the ventilation systems.6 However, closed-loop ventilation systems that do not undergo exchange, in particular, need careful gas monitoring, managing the indoor air quality. Carbon dioxide levels are often used as a proxy for air quality and can be monitored as a way of checking ‘building health’7 and the advantage centralised infrastructure is that is possible to install effective gas monitoring at source that, due to the connectivity of all ducting, will provide effective and inexpensive monitoring for everything that happens downstream. Carbon monoxide monitoring way also be of interest for heating units, as incomplete combustion can lead to the formation of this odourless, highly toxic gas.

Easy Installation Solutions

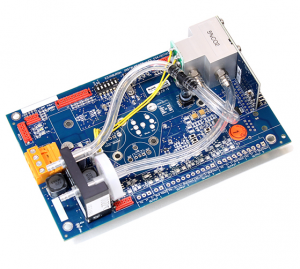

For centralised HVAC facilities, easy to install, low maintenance sensors that can be connected to remote data logging or control systems are the ideal for gas monitoring for environmental optimization and safety. For this purpose, Edinburgh Sensors have developed a range of OEM nondispersive infrared (NDIR) sensors, with excellent accuracy and sensitivity that only require connection to a reference gas for installation.8

For example, the Gascard NG is an NDIR sensor capable of detecting carbon dioxide concentrations over a series of different ranges. For the relatively low short and long term exposure limits as part of indoor air quality applications, devices optimised for low concentrations of 0-10 % may be optimal.9 The excellent limit of detection means even the smallest of changes in gas concentration can be detected, making quick response to a potential problem feasible. The excellent zero stability, which is ±2% of range (over 12 months), also means that the sensor can be a reliable part of any environmental control network. While the Gascard NG is designed up to robust with minimum maintenance, all the parts are field-serviceable so any irregular or unusual maintenance will cause minimal disruption.

This means it is easy to integrate into feedback systems or data logging networks where real-time, regular sampling is required. Additional options include the use of the data logging software provided with the sensor, which simply requires a cable connection to start. For more complex, custom solutions where more extensive integration or advice is needed, Edinburgh Sensors offer full pre- and post-sales technical support and the possibility of bespoke design.

The Gascard NG has been designed to work in a variety of field conditions, including having temperature, pressure, and humidity compensated measurements. The sensor will remain accurate over 0 – 95 % humidity conditions so even in the challenging and potentially highly variable conditions of a centralised HVAC space, the Gascard NG can be relied upon to continue providing accurate readings. It is also possible to collect regular and rapid readouts, with a T90 of just 10 seconds, making the device highly effective for either safety or environmental monitoring purposes.

Stay in touch

If you have enjoyed reading this article about centralised HVAC systems and would like to find out more about our range of gas sensing technology, please don’t hesitate to get in touch with a member of our team today.

In addition, why not join Edinburgh Sensors on social media and sign up to our infrequent eNewsletter to be the first to know about our latest products, research and developments.

References and Further Reading

- UK HSE (2020), https://www.hse.gov.uk/temperature/law.htm, accessed 01/03/2020

- Akimoto, T., Tanabe, S. ichi, Yanai, T., & Sasaki, M. (2010). Thermal comfort and productivity – Evaluation of workplace environment in a task conditioned office. Building and Environment, 45(1), 45–50. https://doi.org/10.1016/j.buildenv.2009.06.022

- Pérez-Lombard, L., Ortiz, J., Coronel, J. F., & Maestre, I. R. (2011). A review of HVAC systems requirements in building energy regulations. Energy and Buildings, 43(2–3), 255–268. https://doi.org/10.1016/j.enbuild.2010.10.025

- Centralized HVAC (2009), http://www.seedengr.com/Cent%20Vs%20Decent%20AC%20Systems.pdf, accessed 04/03/2020

- HSE on SBS (2020) http://www.hse.gov.uk/pubns/priced/hsg132.pdf, accessed 03/03/2020

- Li, J., Wall, J., & Platt, G. (2010). Indoor air quality control of HVAC system. 2010 International Conference on Modelling, Identification and Control, ICMIC 2010, 756–761.

- Bhattacharya, S., Sridevi, S., & Pitchiah, R. (2012). Indoor Air Quality Monitoring using Wireless Sensor Network. Sixth International Conference on Sensing Technology, 422–427.

- OEM Sensors (2020), https://edinburghsensors.com/products/oem-co2-sensor/, accessed 28/02/2020

- Gascard NG (2020), https://edinburghsensors.com/products/oem-co2-sensor/gascard-ng/, accessed 28/02/2020