Landfilled waste and the safe disposal of our day to day rubbish, including plastics, rubber, and non decomposable items, is key to keeping the environment as clean as possible. Waste gasification and the production of syngas plays an important part in this.

Syngas production from waste gasification is one way to produce renewable energy. However, varying waste compositions can make gasification challenging to control, resulting in inconsistent syngas compositions. Closely monitoring gas composition and adjusting process conditions during gasification can ensure consistent, high-quality syngas production. Infrared sensors are the ideal solution for monitoring syngas composition during waste-to-energy processes.

Increasing awareness surrounding the limited and polluting nature of fossil fuel resources has resulted in a significant increase in consumer, business, government, and regulatory demands for green energy over the past decade. Under RE100 many of the world’s most influential companies are committed to using 100% renewable energy by 2020, so demand for green energy is expected to continue to increase.1,2

What is Waste Gasification?

In waste gasification, waste is incinerated via a chemical process in a low-oxygen environment to break it down and remove impurities. Two products are produced as a result of this reaction, syngas and char.

Waste to Energy Gasification

One route to green energy involves gasifying biomass or waste feedstocks to produce syngas, which can then be burned to produce heat and electricity or converted to liquid fuels.3,4

Waste management is an on-going global issue; the world produces 4 billion tons of waste per year. The majority of waste is currently incinerated or sent to landfill. Waste-to-syngas processes reduce the amount of waste sent to landfill by releasing energy from waste while producing fewer emissions compared with incineration.4-6

However, generating syngas from waste comes with some challenges. Waste gasification can be difficult to control resulting in varying syngas quality. Furthermore, impurities and tar formation during waste gasification can make down-stream processing difficult and expensive. As a result, currently, only 0.5% of syngas is produced from renewable resources including biomass and waste.4,7,8

Ideal Syngas Compositions Vary by Application

Syngas is a mixture of carbon monoxide, hydrogen, and small amounts of CO2, methane, tar, water vapor, hydrogen sulfide, and other trace species. It can be produced from virtually any carbon feedstock in a process known as gasification, which involves heating the feedstock to a very high temperature in the presence of a small amount of oxygen. Gasification sounds simple, but it involves a complex combination of chemical reactions and equilibria, resulting in varying syngas compositions.4,9,10

Generalized gasification reaction:

Hydrocarbon feedstock → CO(g) + H2(g) + CO2(g)

Specific chemical reactions involved in gasification:

2C + O2 ⇌ 2CO

C + CO2 ⇌ 2CO

C + H2O ⇌ CO + H2

C + 2H2 ⇌ CH4

CO + H2O ⇌ H2 + CO2

Syngas can be used in many different ways. Heat and electricity can be generated directly from syngas combustion, but syngas can also be converted into liquid fuels including methanol, ethanol, diesel, and gasoline for later use.

Each syngas application places different demands on syngas composition. For example, for methanol synthesis, an H2/CO ratio of 1.0-4.0 is required, combined with a CO2 concentration of 4-8%.4,8-10

Controlling Syngas Production Composition and Quality

Syngas can be made from a wide range of waste and biomass feedstocks including municipal waste, agricultural waste, plastic waste, wood waste, food waste, and cardboard. As the composition of each feedstock varies, so does the composition of the syngas produced.

Other factors that affect the final syngas composition include the composition of the gasification atmosphere, temperature, pressure, residence time, and the presence of any catalysts used during the process.4,11,12

Monitoring syngas composition and varying reaction conditions can help to maintain a constant syngas composition that is suitable for the intended application. For example, injecting CO2 during municipal waste gasification can help reduce tar formation and increase the CO concentration in the resulting syngas.

What’s more, online measurements of the syngas composition can help to identify which gas conditioning processes should be used to obtain the ideal syngas composition. Gas composition monitoring is, therefore, critical during gasification process development and operation.4,13

A number of companies have developed waste gasification technologies. For example, Burkhardt Energy supplies gasifiers that use wood pellets to produce syngas for heat and power generation.

Burkhardt Energy systems overcome problems associated with heterogeneous waste streams by using homogeneous wood pellets, while gas composition measurement systems from Edinburgh Sensors combined with intelligent air and fuel regulation carefully control syngas quality and composition.14,15

Monitor Waste Gasification and Syngas Production with Gas Sensors

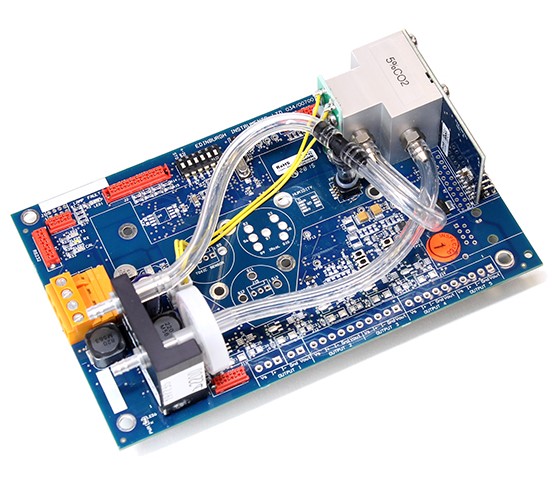

Edinburgh Sensors are a leading supplier of high-quality gas sensing solutions, ideal for monitoring syngas composition during waste-to-syngas conversions. Infrared sensors are easy to use and provide rapid online measurements of CO, CO2, and CH4 concentrations.

Edinburgh Sensors are a leading supplier of high-quality gas sensing solutions, ideal for monitoring syngas composition during waste-to-syngas conversions. Infrared sensors are easy to use and provide rapid online measurements of CO, CO2, and CH4 concentrations.

Edinburgh Sensors offer complete gas monitors (Guardian NG series) and OEM infrared sensors that can be easily incorporated into automated systems that adjust syngas production conditions to maintain gas quality and composition (Gascard NG).

Unlike other available types of sensors, infrared detectors don’t directly interact with the syngas and any contaminants, so the detector is protected from damage. As a result, infrared sensors are robust, low-maintenance, and long-lasting compared with other gas composition sensors.16-19

While some IR sensors suffer from the effects of temperature or pressure variations, sensors from Edinburgh sensors offer extensive temperature and pressure correction to ensure accurate results in a wide variety of gasification environments. Infrared sensors from Edinburgh Sensors provide accurate, reliable gas composition measurements, to ensure consistent, high-quality syngas production.16-19

For further information on our OEM infrared sensors, and how they can be used for syngas production, why not contact a member of our sales team at sales@edinst.com.

References and Further Reading

- ‘RE100 Progress and Insights Report, January 2018’ http://media.virbcdn.com/files/97/8b2d4ee2c961f080-RE100ProgressandInsightsReport2018.pdf

- ‘Competition in Electricity Markets with Renewable Energy Sources’ — Acemoglu D, Kakhbod A, Ozdaglar A, The Energy Journal, 2017.

- ‘Renewable Energy: Sources and Methods’ — Maczulak AE, Infobase Publishing, 2009.

- ‘Progress in biofuel production from gasification’ — Sikarwar VS, Ming Z, Fennell PS, Shah N, Anthony EJ, Progress in Energy and Combustion Science, 2017.

- ‘Progress and challenges to the global waste management system’ — Singh J, Laurenti R, Sinha R, Frostell B, Waste Management & Research, 2014.

- ‘What a Waste’ — World Bank Group, 2012 https://siteresources.worldbank.org/INTURBANDEVELOPMENT/Resources/336387-1334852610766/What_a_Waste2012_Final.pdf

- ‘State of the Gasification Industry – the Updated Worldwide Gasification Database’ — Higman C, International Pittsburgh Coal Conference, 2013.

- ‘Gasification Can Help Meet the World’s Growing Demand for Cleaner Energy and Products’ — Kerester A, Cornerstone: The Official Journal of the World Coal Industry, 2014.

- ‘Report on Gas Cleaning for Synthesis Applications’ https://ec.europa.eu/energy/intelligent/projects/sites/iee-projects/files/projects/documents/thermalnet_report_on_syngas_cleaning.pdf

- ‘Gasification’ — Higman C, van der Burgt M, Elsevier, 2008.

- ‘Waste into Fuel—Catalyst and Process Development for MSW Valorisation’ — Pieta IS, Epling WS, Kazmierczuk A, Lisowski P, Nowakowski R, Serwicka EW, Catalyst, 2018.

- ‘Biomass Gasification: A Review of its Technology, Gas Cleaning Applications, and Total System Life Cycle Analysis’ in ‘Lignin – Trends and Applications’ — K Koido, T Iwasaki, Intech, 2018.

- ‘An Investigation into the syngas production from municipal solid waste (MSW) gasification under various pressures and CO2 concentration atmospheres’ — Kwon E, Westby KJ, Castaldi MJ, Proceedings of the 17th Annual North American Waste-to-Energy Conference, 2009.

- ‘Heat and Power with Wood Pellets’ https://burkhardt-energy.com/download/anpak2lblc01ss6ag75jrtnb360/Burkhardt_KWK_Holzpellets_2018_EN_web.pdf

- ‘Gasification of Waste Materials: Technologies for Generating Energy, Gas, and Chemicals from Municipal Solid Waste, Biomass, Nonrecycled Plastics, Sludges, and Wet Solid Wastes’ —Ciuta S, Tsiamis D, Castaldi MJ, Academic Press, 2017.

- ‘Landfill: High quality gas sensing solutions’ https://edinburghsensors.com/industries/landfill/

- ‘Biogas: High quality gas sensing solutions’ https://edinburghsensors.com/industries/biogas/

- ‘Guardian NG’ https://edinburghsensors.com/products/gas-monitors/guardian-ng/

- ‘Gascard NG’ https://edinburghsensors.com/products/oem/gascard-ng/

- Figure 1: Extraction of non-renewable fossil fuels damages sensitive ecosystems. Image credit: Pixabay.com/MustangJoe

Stay in Touch

To keep up-to-date with our latest news and industry focused articles, why not sign-up to our infrequent newsletter via the button below, and follow us on social media.