Storage of cereal crops and other foodstuffs is an essential part of ensuring a sustainable and robust food supply. Cereal crops are typically harvested between mid-July to mid-September but with careful storage can be kept for periods longer than a year.1 Successful storage of cereals involves the balance of a variety of environmental conditions to ensure the maintenance of quality and the original properties of the grain, including weight and appearance. Ideally, stored grain should be able to match freshly harvested grains in terms of nutrition and appeal.

Poor quality storage not just threatens global food security, a growing concern in a world with expanding populations and energy demands, but also comes with a significant financial cost. Mazie crops lost to poor storage conditions account for $500 million to $1 billion of lost revenue for the developing world alone.2

These are strong motivations to find reliable methods for the monitoring and optimizing of environmental conditions for grain storage. Common reasons for spoilage of stored cereals include water and humidity damage, invasion by insects or microorganisms, or even decomposition.3 Common approaches to kill invasive species were to fumigate storage silos with toxic chemicals4 but this only addresses the issue of damage by organisms and has become generally less popular with time due to concerns about the safety of using such chemicals on foodstuffs. However, it has been found that by using modified atmospheric conditions that, not only can temperature and humidity damage be minimized, but the decomposition rate slowed and even the growth rates of microorganisms minimized.5

Modified Atmospheres

Modified atmospheric conditions mean an environment that deliberately has its gas composition controlled, often by complete replacement of the local atmosphere with a combination of deliberately chosen gases.6 These are commonplace in all areas of food preservation, from the packaging on supermarket shelves for meat and vegetables, to their use in storage silos for cereals.

Some of the advantage of using modified atmospheric conditions for cereal storage over traditional physio-chemical methods is that there are fewer safety concerns associated with the use of chemical products and several contributors to cereal spoilage can be tackled with the same process. For example, one of the most common causes of food spoilage in humid areas is the uptake of water by the cereal, which often leads to mold growth and decomposition. Reducing the humidity in the environment does not just have to be done with a physical dehumidifying process, such as using a refrigerant to condense water out of the air, but can be done by increasing the nitrogen concentration. Increased nitrogen and oxygen concentrate can also be used to kill insects and microbes.7

One gas that is often carefully controlled in modified atmospheric conditions is carbon dioxide. Carbon dioxide is often used in high concentrations to inhibit insect life in the cereal8 for preservation, but detection, of carbon dioxide levels can be very useful as an indicator of spoilage of crops.8 As decomposition of the cereal starts to occur, a combination of carbon dioxide, and highly toxic carbon monoxide, are produced and this can be used as a diagnostic for the quality of the storage.9 One of the issues, if decomposition occurs due to the presence of microorganisms, is if the problem is not rectified quickly, the microorganisms will continue to grow and more of the cereal will be wasted.

Sensitive gas monitors can, therefore, help not just to ensure modified atmospheric conditions are optimal but to check for signs of spoilage, or also the formation of toxic gases. Grain silos will can become anaerobic environments and spoilage can produce large volumes of carbon dioxide, which could lead to the asphyxiation of workers and so gas monitoring is required as part of health and safety legislation.10

GasCard NG

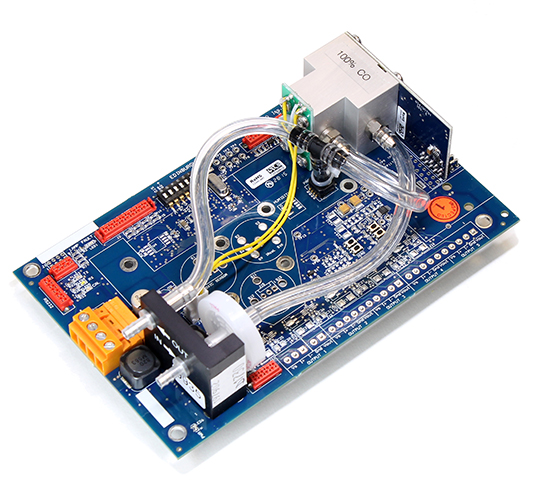

Many cereal storage facilities are retroactively fitted with modified atmosphere equipment and so easy to install and robust independent gas monitors are the perfect complement for that. To that end, Edinburgh Sensors offer a wide range of OEM gas sensors based on nondispersive infrared (NDIR) technology, a highly sensitive and accurate approach for the detection of many gaseous species such as carbon dioxide and carbon monoxide.11

For cereal storage facilities, Edinburgh Sensor’s GasCard NG is the ideal way to ensure optimal storage conditions for crops.12 As the device is calibrated in factory, no reference gas is required, (the detector is suitable for use with a series of different gases but one device can detect one gas sat a time), and installation and use is designed to be as straightforward as possible. As in the case of spoilage the change in carbon dioxide levels may be very small, the accuracy of ±2% in measuring carbon dioxide concentrations between 0 – 100 % is ideal.

The GasCard NG can easily be connected to external data logging devices using a RS232 interface or TCP/IP protocol. As the sensor is provided with logging software, it only needs a connecting cable to be purchased to be up and ready for real-time data logging. With a short warm-up time of a minute and a response time of less than 90 seconds, the GasCard NG is also suitable for high throughput measurements on a rapidly changing and complex environment of a storage silo, ensuring problems can be detected and solved before they evolve any further and significantly reducing food spoilage.

For more information about our GasgCard NG or our other gas sensing products, please get in touch today. If you have enjoyed this article and would like to read more, why not sign up to our eNewsletter and join us on social media.

References and Further Reading

- Fleurat-Lessard, F. (2003). Physico-Chemical Treatment. In Encyclopedia of Grain Science (pp. 254–263).

- Shiferaw, B. et al. (2019). Crops that feed the world 10. Past successes and future challenges to the role played by wheat in global food security. Food Secur., 2013, 5, 291–317.

- Suleiman, R. et al. (2013). Effects of Deterioration Parameters on Storage of Maize, Nat. Sci. Res., 3, 147–165.

- Navarro, S., and Navarro, H. (2016). Emerging Global Technological Challenges in the Reduction of Postharvest Grain Losses. Proceedings of the 15th International Cereal and Bread Congress, 39.

- Calderon, M. and Barkai-Golan, R (1990) Food Preservation by Modified Atmospheres

- Correct Gas Concentrations for Atmospheric Packaging, (2018), https://www.azosensors.com/article.aspx?ArticleID=1012 accessed 28/02/2020

- Jayas, D. S. and Jeyamkondan S. (2002). Modified atmosphere storage of grains meats fruits and vegetables, Eng., 82, 235–251.

- Pekmez, H. (2017). Cereal Storage Techniques: A Review, Agric. Sci. Technol. B, 6, 1–6.

- Whittle, C. P., Waterford, C. J., Annis, P. C., & Banks, H. J. (1994). The production and accumulation of carbon monoxide in stored dry grain. Journal of Stored Products Research, 30(1), 23–26. https://doi.org/10.1016/0022-474X(94)90269-0HSE on Carbon Dioxide, (2020) http://www.hse.gov.uk/carboncapture/carbondioxide.htm, accessed 28/02/2020

- OEM Sensors (2020), https://edinburghsensors.com/products/oem-co2-sensor/, accessed 28/02/2020

- Gascard NG (2020), https://edinburghsensors.com/products/oem-co2-sensor/gascard-ng/, accessed 28/02/2020