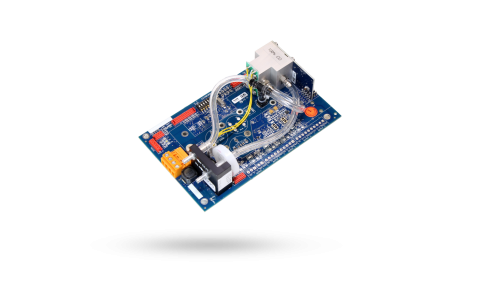

Boxed Gascard®

The Boxed Gascard is the latest development in the NG range of products from Edinburgh Sensors.

Extending the shelf-life of perishable foods.

Modified atmosphere packaging (MAP) is a method of packaging food products that helps to maintain the freshness and extend the shelf life of the product. MAP enables fresh and minimally processed packaged food products to maintain visual, textural and nutritional appeal.

Modified atmosphere packaging consists of the optimal blend of atmospheric gases within a high barrier or permeable package. These gases include a finely balanced mix of pure oxygen, carbon dioxide and nitrogen.

The packaging can include plastic films, foils and other packaging materials with specified gas or water permeability. The atmosphere within these high barrier substrates is controlled through a precisely adjusted gas blend which provides the specific respiration needs for each food product. For example, meats generally benefit from a MAP containing 70-80 % oxygen, whereas seafoods and shellfish usually benefit from low oxygen levels and more carbon dioxide.

Each aspect of the MAP needs to be carefully controlled at each stage. For example, the film permeability, water transmission rate and sealing characteristics need to be tested at selection, package converting and product fill stages as the ability to capacitate gas blend may vary.

Through the precise control of the package’s gaseous environment, the shelf life of the product can be extended without the requirement of adding chemical preservatives or stabilisers. The ageing process is slowed down which reduces colour loss, odour and off-taste resulting from product deterioration, spoilage and rancidity that can be caused by mold and anaerobic organisms.

As a result, manufacturers will have more control over product quality, availability and costs. They can eliminate product rotation, removal and restocking which will reduce labour and waste disposal costs. Furthermore, distribution territories can be widened and product replacement cycles extended which reduces production replacement demands. As a result, overall profits will be maximised.

At Edinburgh Sensors, we understand that processors of food products rely on Modified Atmosphere Packaging in order to meet customer expectations of fresh and appetising products.

The following of our gas sensors are ideal for use within Modified Atmosphere Packaging. Have a browse and if you would like to discuss your requirements with a member of our team, please contact us today.

The Boxed Gascard is the latest development in the NG range of products from Edinburgh Sensors.

The Gascard NG infrared gas sensor is designed for ease of integration with a wide range of gas detection systems that require high quality, accurate and reliable measurement of CO, CO2, CH4 gas concentrations.