NDIR CO2 Sensors have evolved over the years from mercury-based manometers to large, bulky NDIR technology to the smaller, much more suitable CO2 sensors for modern solutions. This article explores what an NDIR Sensor is, why they are needed and in which industries they are useful as well as suggesting Edinburgh Sensor products to meet your CO2 sensor requirements.

What is an NDIR CO2 Gas Sensor?

Detecting carbon dioxide became a challenge as soon as the gas was discovered in the mid-18th century. For early CO2 detection, mercury manometers were accurate and reliable, but samples could take hours to analyze. As the need to monitor CO2 concentrations became more apparent, the first NDIR CO2 Sensors were designed. These gave almost instant results. Over time, technology has allowed CO2 sensors to decrease in size, making them much more compact and convenient for use in a number of different industries.

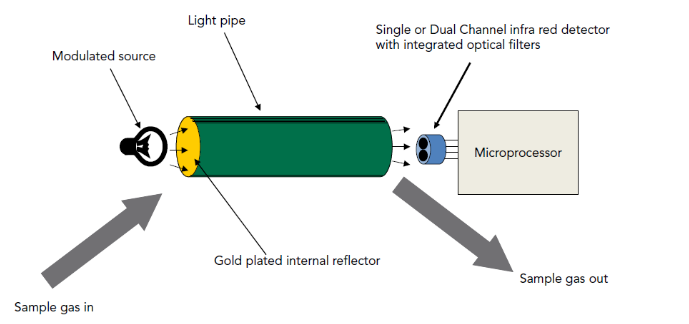

NDIR (non-dispersive infra-red) CO2 detectors work based on CO2 absorbing infra-red light at a specific wavelength, so it is easy to distinguish from other gases (many commonly detected gases have unique infrared wavelength absorption wavelengths).

A light source emits infra-red light which is passed through a sample chamber where the air sample enters. An IR sensor is placed at the opposite side of the chamber with an optical filter in front of the sensor so only the desired wavelength is detected. As more CO2 gas molecules enter the sample chamber, absorbing the light, less IR light is detected by the sensor.

Why do we need to monitor CO2?

A build up of CO2 can result in a variety of health complications for humans. At low concentrations, symptoms of CO2 exposure include headaches, dizziness, and tiredness but at very high concentrations, CO2 exposure can even cause convulsions, a coma or death.

There are several industries where there is a risk of CO2 build up that could result in health issues for employees. One solution to this is to install an NDIR CO2 gas sensor to monitor CO2 levels in the air.

In some industries, monitoring CO2 is not only a health and safety issue. It is also important to monitor the air CO2 concentrations for quality purposes or efficiency purposes.

Industries that can benefit from an NDIR CO2 Gas Sensor

NDIR CO2 gas sensors are necessary in several industries where there is a risk of CO2 exposure, poor ventilation, or where CO2 levels are important for product quality. This includes:

- Agriculture – CO2 concentrations must be monitored for different reasons in the agriculture industry. This includes crop growth, gas stunning in livestock slaughter and preventing the spoilage of crops.

- Landfill – As waste breaks down in landfill, landfill gas (a mixture of CO2, CH4 and some other gases) is produced by microorganisms. Monitoring this gas is required as legally the landfill gas must be safely removed to avoid an explosion from pressure build up.

- Total Organic Carbon (TOC) – TOC analysis can indicate water quality. By oxidizing the organic carbon in a sample to produce CO2 and by measuring that using an NDIR CO2 gas sensor, we can convert the value into a TOC measurement involving the subtraction of the ‘inorganic carbon’, which is the content of dissolved carbon dioxide and carbonic salts.*

- Biogas – CO2 levels can indicate the efficacy of the anaerobic digestion during the fermentation process.

- Process Control – CO2 and CO concentrations must carefully be controlled in heat gas treatments to ensure that carburising is successful.

- HVAC – HVAC systems monitor the quality of air indoors and in vehicles to optimize wellbeing and safety but also cost effectiveness.*

- Horticulture – Controlled Environment Horticulture systems are designed to protect, maintain and optimize the growing conditions of crops. Whilst CO2 concentrations are important, other conditions such as temperature, light, humidity, pH, and nutrients must also be monitored closely.

- Modified Atmosphere Packaging – Optimizing a blend of atmospheric gases (oxygen, carbon dioxide and nitrogen) is necessary to ensure the quality and longevity of packaged foods. Specific blend conditions are required for different products (such as meat vs shellfish) and at different stages of the packaging process so it is necessary to constantly monitor gas concentrations.

- Controlled Atmosphere Storage – Similar to Modified Atmosphere Packaging, Controlled Atmosphere Packaging uses a precise blend of oxygen, carbon dioxide and nitrogen to optimize storage conditions of food products such as fresh fruit and vegetables to maximise their quality and shelf-life by slowing down food degradation.

*Please note that whilst some of the applications where our products can be used are in TOC analyzers and HVAC systems, we do NOT manufacture these.

NDIR CO2 Gas Sensor from Edinburgh Sensors

Edinburgh Sensors offers several solutions to your CO2 sensor requirements, depending on your exact needs.

The Gascard NG is designed to be easily incorporated into a range of CO2 sensor systems that require high quality, accurate and reliable measurement of CO2 concentrations.

The Boxed Gascard® provides users with access to the Gascard NG range of CO2 detection products in a convenient and robust desktop unit. Requiring only a suitable power supply and sample gas, the Boxed Gascard® provides fast and reliable CO2 concentration data over a wide range of barometric pressures and environmental temperatures.

The heart of the Boxed Gascard® is the Gascard NG which uses a pseudo dual beam NDIR measurement system for increased stability and the reduction of long-term drift with minimum optical complexity and no moving parts.

The Guardian NG for CO2 sensing offers continuous sampling, measurement and display of target CO2 concentrations to ensure real time results for you, ensuring CO2 levels stay at an appropriate concentration for the environment and keeping staff safe.

If you would like to speak in more detail about your NDIR CO2 Sensor requirements, get in touch with our sales team who will be happy to help you find the product most suitable for your needs.

Keep in Touch

If you have enjoyed this article, be sure to subscribe to our newsletter and follow us on social media using the links below.